Smart Industries

Inspiring Leap into the Grocery Business with RFID Technology

Smart Industries

Medigas Italia is digitizing the distribution of its home-based oxygen therapy services. With an RFID solution leveraging Confidex’s on-metal labels the company is saving 20 minutes with every truck loaded.

Medigas Italia is digitizing the distribution of its home-based oxygen therapy services. With an RFID solution leveraging Confidex’s on-metal labels the company is saving 20 minutes with every truck loaded.

Challenges

Benefits

Medigas Italia is a Milan-based provider of life saving supplies used by patients, throughout Italy, who require oxygen therapy or ventilation services. Patients in need of oxygen therapy are typically suffering from asthma or chronic obstructive pulmonary disease, (COPD). In fact it’s estimated that COPD is the third cause of death in the world, following coronary and cardiovascular disease. Additionally, oxygen therapy is used for patients suffering from heart disease or neurological disorders.

The COVID-19 pandemic has provided an additional challenge for healthcare providers, and for Medigas, as more patients are suffering from long-term respiratory disease. In many cases, its ventilators and other therapeutic and diagnostic equipment and services are what helps individuals to remain in their homes.

However, tracking and managing the equipment used in hundreds of homes across the country poses a unique challenge that requires highly accurate data about movement of inventory and assets.

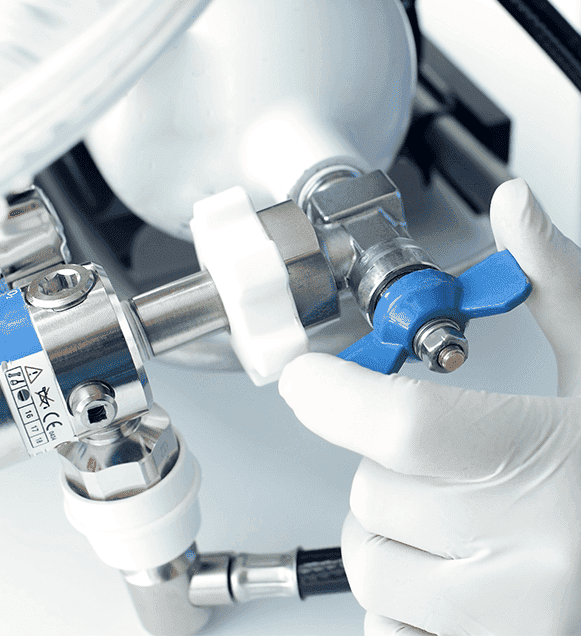

The company opted to deploy a system that leverages TSL’s handheld barcode scanner and UHF RFID reader, a Zebra printer, Confidex on-metal labels, and an integrated data management solution. With the technology, Medigas is uniquely identifying each one of its respiratory therapy assets as they are delivered to patients, returned to its own facility, as well as maintained inspected and serviced.

To ensure that every item is properly tracked, Medigas needed a reliable mount-on-metal label with flexibility for use across many form factors. Those labels are applied to cryogenic cylinders and other metallic equipment before they are sent to individual homes. The company chose the Confidex Silverline family of RAIN RFID labels. The Silverline industrial grade, printable, on-metal labels are designed for durability and flexibility. The products boast various sizes, each with durable PET face material for durable printing and industrial grade adhesive for challenging environments.

“The new enhanced Silverline family is offering exceptional performance on any surface,” says Confidex’s Miika Pylvänäinen, Director of Product Line RFID. “This improves inventory accuracy with applications such as healthcare that involves a lot of different type of assets including various surface materials from metals to coated metals and plastics.”

Learn more about Silverline products.

Today Medigas is automatically capturing the identity of each piece of equipment as trucks are loaded prior to delivery at customer sites. By identifying the tags on site instantly, before the truck leaves, workers have saved an average of 20 minutes per truck. In fact, the company says tags can typically be read in a truck within a few seconds.

And the gains are not only in efficiency, but also accuracy. By employing the RFID system, workers can now capture serial numbers for each item automatically, which means they reduce the potential for human error. And with this new automated data capture, the company can view exactly what was loaded on each transportation vehicle from the office or other remote location.

Medigas also shares documentation related to pick up and delivery in real time with customers so that they too can view when and where equipment was loaded or unloaded from trucks.

The technology provides even more applications that include automatically generating bills and invoices, real time inventories and automatic replenishment orders of supplies. The respiratory solutions company can also use the technology to automatically open gates, and to authorize the operation of machinery to properly trained individuals. The system can even help Medigas manage maintenance and testing of its life saving assets. Ultimately the solution has ensured that Medigas provides the equipment needed for each patient, where and when it is needed.